Induction vs Traditional Gas Which One is Right for You? Breakthrough Blacksmithing

The Induction Forge Guide Updated October 5, 2023 I used an induction forge for the first time at Clay Spencer's shop in 2019. I was immediately intrigued by the machine and knew I could make use of one in my shop.

Home ISF Induction Solution ISF

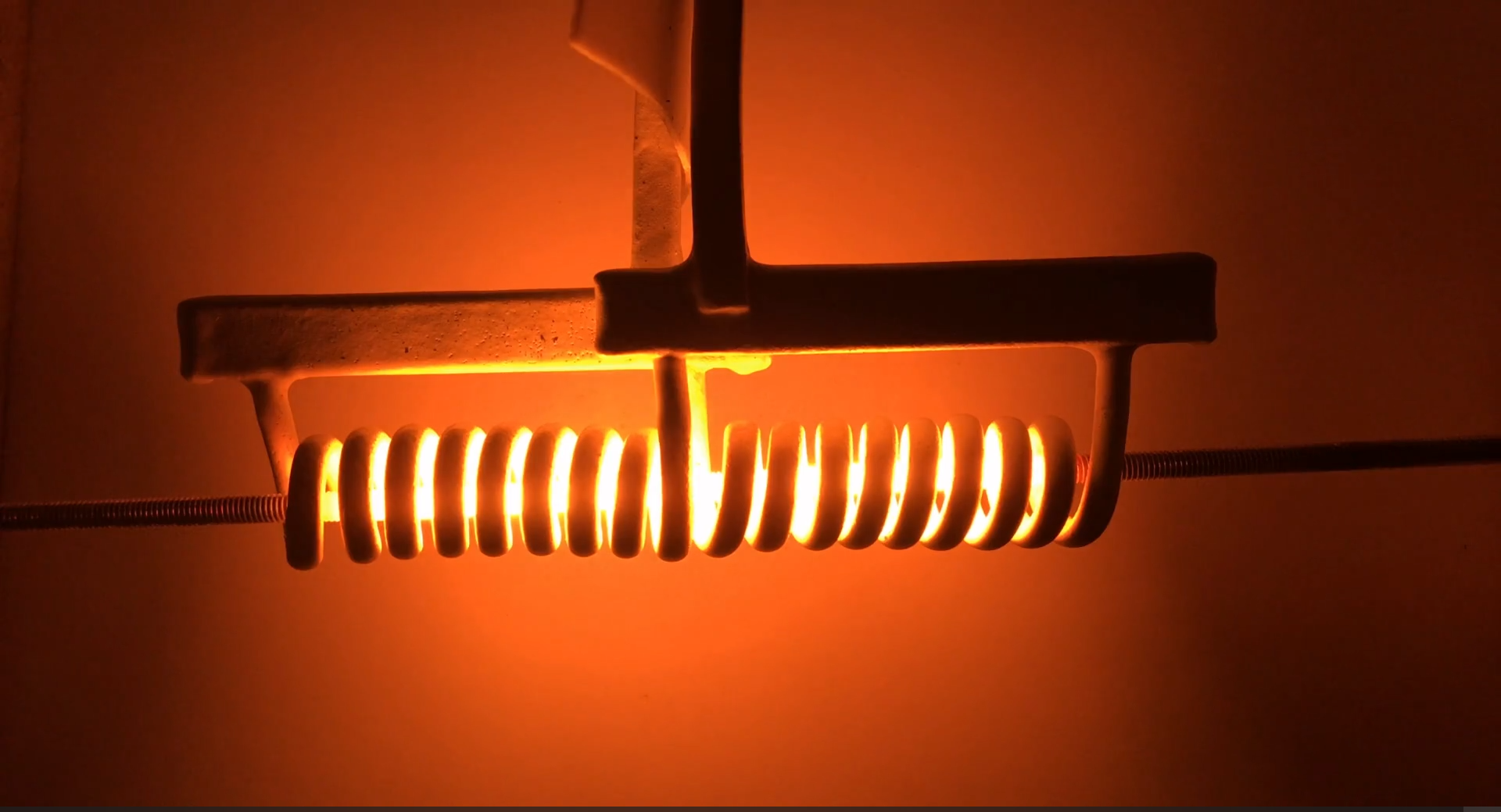

Induction forging refers to the use of an induction heater to pre-heat metals prior to deformation using a press or hammer. Typically metals are heated to between 1,100 and 1,200 °C (2,010 and 2,190 °F) to increase their malleability and aid flow in the forging die. [1] Process

Induction Kit for Audi TTS VRS Northampton

The advantage of using an induction forge for blacksmithing is that it is an energy-efficient and easily controlled heating process compared to most other means of metal melting. They can be more expensive to set up, depending on your access to power at home. Power supplies can vary in frequency from 50 Hz to 200 kHz, exceeding typical.

FMINDK18 Induction Kit UroTuning

Ive wanted an induction forge for a long time, after setting this one up, WOW i should have gotten one sooner. Its a significant investment at around $1600,.

An induction furnace is an industrial equipment that uses induction heating technology

15KW Induction Forge - Coal Iron Works INTERNATIONAL ORDERS: Please email [email protected] for a shipping quote The Coal Iron Works Induction Forge is used for quick and precise heating operations during forging and heat treating. Amperage control is provided to dial in the heat you need.

Induction for Knife Making Induction Heater for Knife Making

Induction forging is a quick and energy-efficient process used to heat materials using induction heating prior to forming them to your desired shape. Whether it be billet, bar, slab, or other, the induction forging processes delivers superior productivity, part quality, equipment reliability, and work cell flexibility.

Induction

Induction forge- My experience. Blacksmithing. Javos_Ironworks October 26, 2017, 2:21pm 1. Induction forge-. I've had a number of people ask me about this machine so I thought I would add some insights here. I recently purchased a Induction forge with the idea it would help make it tolerable forging in the hot summer months.

Where o where Induction Page 3 Induction Heating, Oil etc I Iron

Salut à tous, j'espère que la vidéo vous a plu.N'hésitez pas à vous abonner, liker et partager pour plus de vidéos.Ajoutez-moi sur snapchat si vous avez des.

Induction YouTube

induction forge for steel bars. A 15 kW induction forging machine with all the necessary equipment costs between $930 and $1800. You can choose the machine according to the size of the part you want to heat. But before buying, please confirm with the dealer or manufacturer that the machine is suitable.

FMINDK18 Induction Kit UroTuning

How Induction Forging Works Induction forging combines precision, control, economics and safety, focusing heat only on the portion of the material to be forged, efficiently producing the malleable temperature. Contact Us Home Applications Forging Page contents: Benefits | Application Notes | FAQs | Popular Video & Note | Brochure Offers

induction Cdiscount

I was basically under the impression that there were no small, craft level induction forges on the market. So, I was very surprised to find not one but two on Amazon. The first one looks pretty much exactly like mine. I think I paid around $2,000 for mine (I can't remember exactly), but this one is under $600.

Française d’Induction Spécialiste de la et de la Fonderie

An induction forging furnace offers the technician more accuracy throughout the heating process, ensuring the results are as precise and uniform as possible. If you have smaller parts to work with, then an induction forge is exactly what you need. It offers a more ideal scale for getting those small pieces to shape perfectly, without hurting.

Pin on DESIGN

Induction forging is a process in which an induction heating system preheats metals and presses them into shape using a hammer or press. The applications for induction forging vary greatly, but before you get started assessing your applications, it's helpful to have a good understanding of the process. So, let's get started.

Induction kit for Mini Countryman Cooper S R60 from PRS Racing UK

Inductoheat - Induction Forge Heating Technology is used for heating a wide range of bar and billet diameters. Built to thrive in aggressive forging environments, the Inductoforge ® power supply is the latest generation of an industrially proven system.

Induction My experience Blacksmith Forums

About Induction Heating Warranty How to Order The SP-15A a 208-240v Single Phase Machine With enough capacity to heat 1.5" bar stock. Specifications: ★ Input voltage : Single-phase 208-240V, 50 or 60 HZ ★ Max input current : 32A, ★ Output Oscillation Frequency : 30-100KHZ ★ Solid State Power ★ Duty cycle : 80% ★ Max input power : 7KW,

COMMENT FAIRE UNE A INDUCTION ULTRA PUISSANTE !!! YouTube

built by [bwang] over on Instructables. It gets hot enough to melt and forge steel, iron, and aluminum. this induction heater from a few years ago. A little smaller, but still usable. Posted in.